Centroid CNC control sales, service, training and support

These controls are designed for do-it-yourself retrofits, ideally on machines already equipped with older DC-servo control systems such as Boss 9, Boss 10, Prototrak, Anilam, Dynapath, etc..

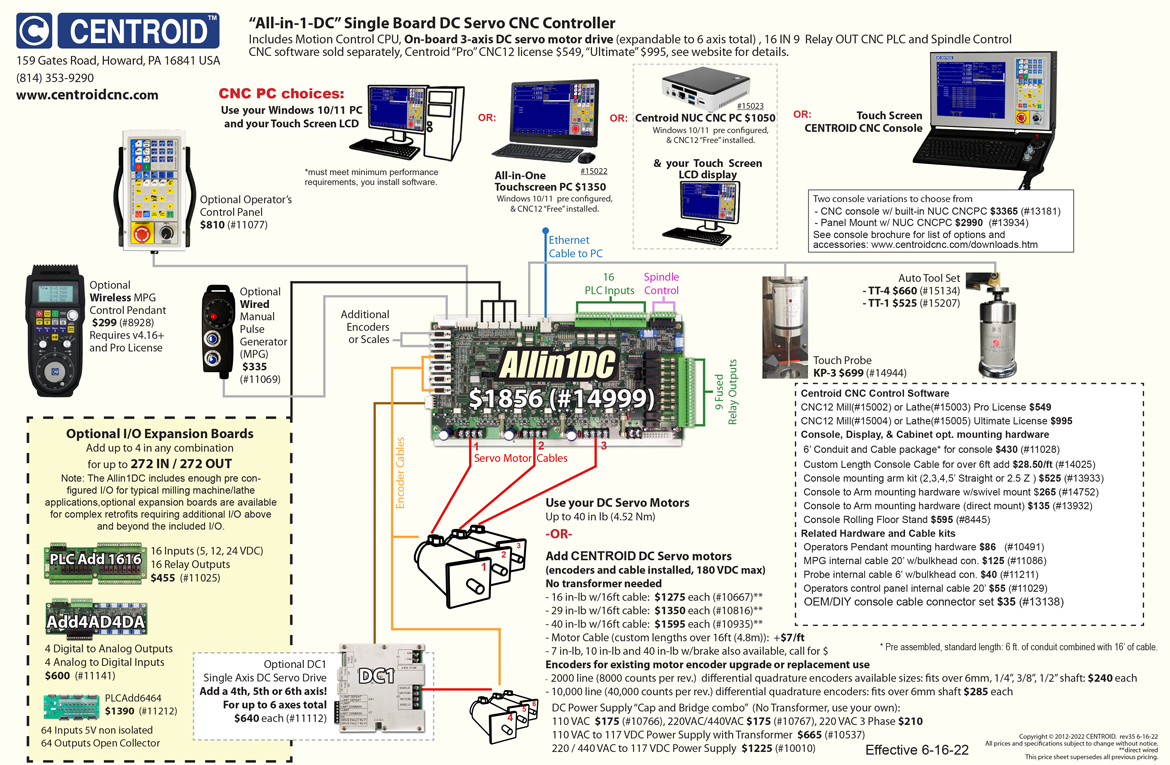

The heart of the system is Centroid's All-in-One DC control unit, which combines the MPU11 motion controller with a three-axis DC servo amplifier and PLC input and output features.

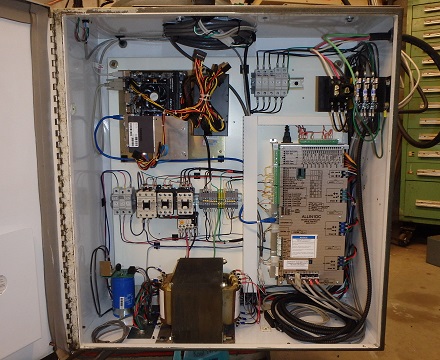

This kit includes the All-in-One DC control unit, handheld control pendant, 120VDC power supply, Emergency Stop contactor and reversing spindle contactors, all assembled into a NEMA 12 enclosure.

Three new 2000-line (8000-count) rotary position encoders are included, which you would mount to your existing servo motors.

Centroid control software for Windows is included.

You would need to provide a suitable computer with Microsoft Windows 7 or 10, and a keyboard and monitor, and you would need to adapt or replace your existing servo motor cables.

The most basic kit includes the All-in-One DC control unit, handheld control pendant, and Centroid control software for Windows.

| All-in-one DC control unit | $1,856 |

| Handheld control pendant | $810 |

| Software and documentation download | n/c |

| "Pro" level mill or lathe software license | $549 |

| Total for basic kit | $3,215 |

This is sufficient for a retrofit if you can re-use your existing servo motors and encoders; your existing DC servo power supply (from 20 to 160 VDC); and your existing contactors.

The retrofit shown at right consists of the above components plus the Centroid servo power rectifier (cap and bridge assembly), installed into the original cabinet of an old Dynapath Delta 10 system on a Webb mill.

We were able to use the original transformers, contactors, motors,

encoders and cables.

At left is a similar installation using the original Centurion V cabinet

on a Milltronics Partner II.

At left is a similar installation using the original Centurion V cabinet

on a Milltronics Partner II.

Again, we were able to use the original power distribution, transformers and contactors. We were also able to use the original servo power rectifier (bridge and cap).

The original servo motors were suitable, but required new encoders.

The original encoders were a "differential open collector" type, which is

not the same as a line driver type. While they could probably have been

used with the addition of a pull-up resistor network, it was not worth

adding that complexity when new, reliable line-driver encoders are

readily available.

At right is another early Dynapath cabinet, this time on a Clausing-Kondia

knee mill.

At right is another early Dynapath cabinet, this time on a Clausing-Kondia

knee mill.

In this case we used little except the enclosure and the main power switch. We added a Centroid transformer and servo power supply assembly; new fuses; and new contactors.

The original X and Y servo motors and encoders were suitable for re-use.

The customer installed an Elrod quill drive system, to convert the machine

from two-axis CNC to full three-axis CNC, and therefore added a new servo

motor for the Z axis.

For additional examples of control cabinet layout with the All-in-one DC unit, see Centroid control upgrades with All-in-one DC

Additional components can be included as needed:

| New 8000-count encoders (each) | $240 |

| Servo power supply: 120VAC to 120VDC and 24VAC | $665 |

| Servo power supply: 208-240VAC or 416-480VAC to 120VDC, 120VAC and 24VAC | $1,225 |

| Servo power rectifiers: 85VAC or 170VAC to 120VDC (use with your transformer) | $175 |

| 29 in-lb DC servo motor with encoder & cable | $1,350 |

| 16 in-lb DC servo motor with encoder & cable | $1,275 |

| Manual pulse generator (electronic handwheel pendant, MPG) w/6' cable | $460 |

| Wireless MPG (electronic handwheel pendant) | $299 |

The standard software supplied with each kit includes:

All applicable Centroid options and accessories are also available for these control kits.

Copyright © 2022 Marc Leonard

Last updated 28-Jul-2022 MBL